what we do

From concept design to long-term plant performance, our offerings cover the full lifecycle of engineering support.

Whether you are upgrading existing equipment, increasing production, or building a new process line, we provide the technical accuracy, project discipline, and industry-specific knowledge required for safe, efficient, and compliant operations.

Consulting

Technical guidance rooted in real-world factory experience.

We help you make informed engineering decisions by analysing your current setup, identifying risks and bottlenecks, and proposing practical, cost-efficient improvements. Our consulting work ensures every step is grounded in process reliability, hygienic design, and operational feasibility.

Read more →

Engineering

End-to-end engineering for liquid food processing systems.

We specialise in designing hygienic process lines, including filtration and mixing processes, storage, thermal treatment, and CIP systems. Every design is tailored to the customer needs, compliant with industry standards, and optimised for consistent product quality and operational efficiency.

Read more →

Project Management

Professional execution from planning through commissioning.

Our project managers coordinate engineering activities, suppliers, documentation, timelines, and on-site execution to ensure projects are delivered safely, on schedule, and according to specification. We provide clear reporting and full technical oversight throughout all phases.

Read more →

Equipment Supply

Special equipment tailored to each customer’s specific operational needs.

We supply key components, systems, and process equipment selected to match your technical requirements and production goals. Every item is backed by documentation, engineering guidance, and integration support from our team.

Read more →

Post-Sales Support

Long-term technical support to keep your plant running reliably.

We assist with maintenance planning, troubleshooting, inspections, operator guidance, and optimisation of existing systems. Our service philosophy is simple: fast response, clear technical communication, and practical solutions that minimise downtime.

Read more →

Built on proven engineering, clear communication, and dependable support.

Consulting

We provide independent technological and technical consulting including independent technical audit and analysis, concept development and project management consulting. Our focus is on quality, automation, environment, maintenance, service, and support. Our approach is based on five milestones.

Why consider an external expert?

Consulting Types

Our consulting offerings include independent technical audit and analysis, concept development and project management consulting.

Independent technical audit and analysis

Together with the partners we:

- analyse and advise on a dairy technology in areas of milk and whey ingredients production,

- identify areas for improvement to optimize productivity and costs,

- advise on a specific technical/technological issues.

We focus on technological processes for:

- Production of whey ingredients

- Production of milk ingredients

- Baby food

- Production of the fresh dairy products as milk, dairy fermented products, chesses, etc.

- CIP systems and utilities

Concept development together with the client

Conceptual design and our expert services help clients to clarify questions like:

- Which products will be produced? With which quality? In which packaging?

- How existing production processes can be improved?

- Can be consumption of water, energy, cleaning agents as well as product losses reduced?

- How quality risks can be avoided?

- How can the data from supervising systems be used for effective production management?

Project management consulting

It can make a significant difference to have an independent experienced expert to:

- evaluate technology and process

- estimate and prioritize possible areas for improvement

- implement new technologies

We Focus On

Quality

We analyse current situation and suggest improvements to reach required level of quality and reduce quality risks.

Automation

We analyse current situation and suggest improvements to reach required level of quality and reduce quality risks.

Environment

We analyse current situation and suggest improvements to reach required level of quality and reduce quality risks.

Maintenance, service, and support

We analyse and suggest improvements to customer’s maintenance, service and support procedures and practices to allow reduction of overall production costs.

Our Approach

Gather information and develop baseline (as-is status). Determine pains and prioritize areas of possible improvements together with the customer

Identify possible improvements

Quantify investment requirements for improvenments against expected benefits

Define goal – identify and prioritize activities to build required capabilities

Create an action plan

Engineering

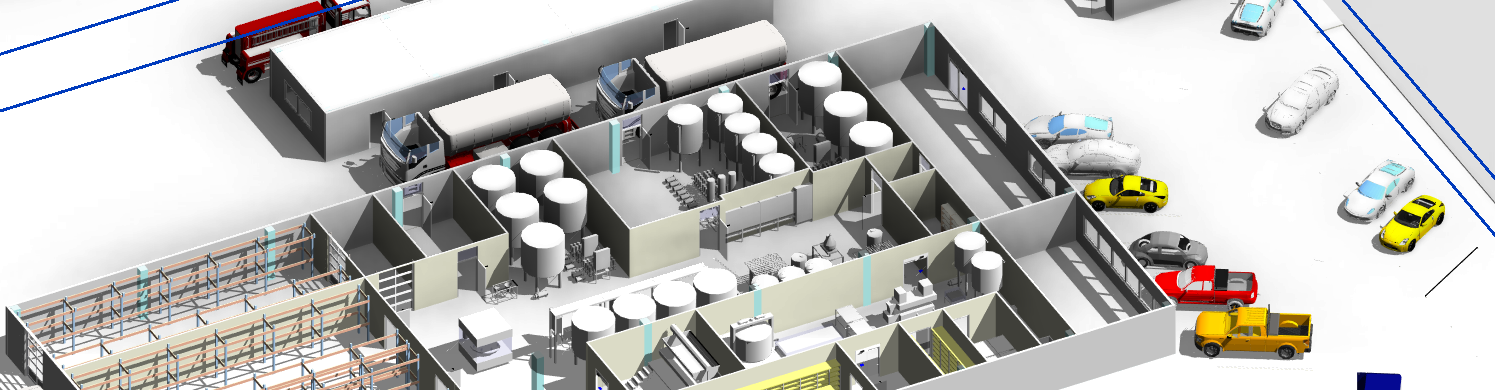

Our engineering services transform your concept into a fully designed and technically validated process system. From basic design to detailed 5D modeling, we develop process layouts, integrate new equipment, and ensure technical precision at every stage of the project.

Basic Design

Basic project design is done after project goals are defined in the phase of conceptual design.

Key questions addressed

- How are our goals achieved?

- Which production processes are needed to achieve goals?

- What main equipment is needed?

- How to include new equipment into the existing process?

- How much space is required for the project?

- What are the utility requirements?

- What is basic project schedule?

- What budget is necessary for investment?

Basic project design documents

- Basic process description preparation

- Basic process flow chart preparation

- Basic equipment layout preparation

- List of main equipment preparation

- Estimation of utilities consumptions

- Basic project schedule estimation

- Budget estimation of project value

- 3D basic model design

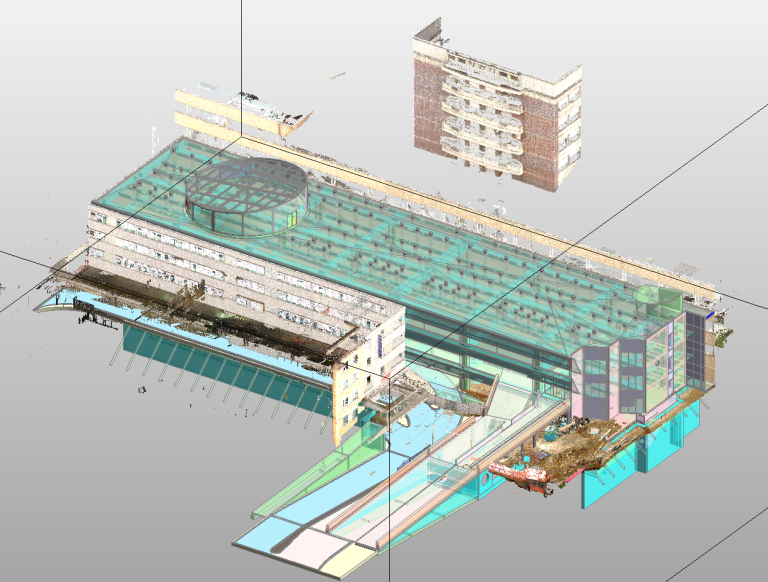

- 3D scan of existing facilities

Our Approach

Existing products and technological process review

Existing technical documentation review

Facility audit

Detailed Design

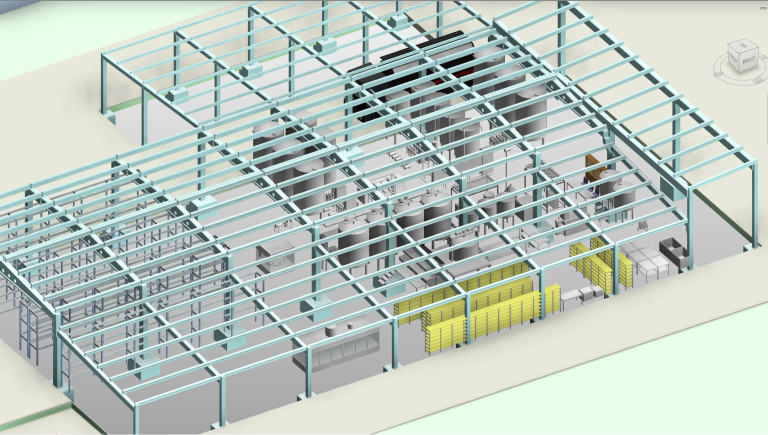

We offer innovative 5D detailed engineering which allows effective control for technological and construction part of the project.

5D process engineering

5D detailed process engineering & controlling includes:

- 3D model

- time control option(4D)

- costs control option(5D)

5D approach allows client to have good control over costs of implementation and project schedule.

Using 5D engineering & project management help client to avoid unpredicted costs and allow to implement the project in planned time.

Client can order 5D detailed process engineering & controlling

- as a part within the turn key project

- as a separate service

Detailed project design documents

- Detailed process description

- Detailed process flow chart – P&ID

- Detailed equipment list

- 3D model of building and equipment

- Utilities consumption estimation (steam, water, ice water, electricity, etc.)

- 3D model of product and CIP and other installations

- 3D model of utility installations

- Definition of process limits – connecting points with other systems

- Preparation of process automation concept

- Preparation of time plans

- Consulting for civil works related to process equipment

Project Management

Bering provides complete turnkey project management — from planning and contracting to commissioning and handover. With certified project management and multidisciplinary expertise, we coordinate suppliers, schedules, and quality control to deliver reliable and on-time project execution.

Project Management & Implementation

We offer several options for the implementation of “turnkey” projects, depending on the resources and needs of the client. Prior to implementation, the division of responsibilities between client and supplier is determined.

For the needs of project implementation, we offer:

concept preparation

design

production of automated process technological equipment

installation and commissioning

post-sales support

Bering manages turnkey projects in accordance with the scope of work specified in the contract.

Project management

We work with Project Management Professional (PMP) certified by Project Management Institute (PMI). We offer project management consulting in areas of:

- products and capacity selection

- equipment definition

- preparation of process flows and building requirements

- feasibility studies

- option appraisals

- dairy factory design

- tender management

- supervision

- installation

- training

- commissioning

Contracting

- Investment cost estimation for tender activity

- Request for quotation (RFQ) tender documentation preparation

- Collection of the turn-key offers

- Consulting during contracting phase

Supervision of mechanical and electrical installation

- Project schedule – coordination with investor and suppliers

- Consulting regarding equipment definition

- Technical and technological consulting regarding automation functions

- Design qualification (DQ) supervision

- Control of supplier’s production during implementation phase

- Supervision of FAT tests of equipment before delivery

Participation in start-up works

Dry tests (IQ – installation qualification)

Wet tests (OQ – operational qualification)

CIP validation procedures

Performance tests (PQ – performance qualification) ¸

Participation in training

Collaboration with customer during first production tests

Preparing final project documentation

Starting new process production is always a great opportunity for business, which also carries a responsibility and risks connected with it. Capitalizing of that opportunity and reducing the risks greatly depends on the installation partner.

Whether it’s a greenfield plant or expansion of existing operations, with Bering by your side you can count on finishing project to the very end. When your equipment is installed and running.

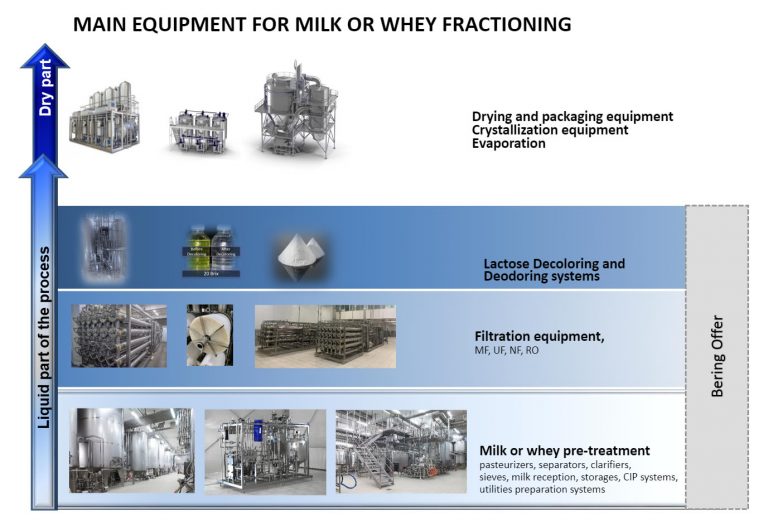

Equipment Supply

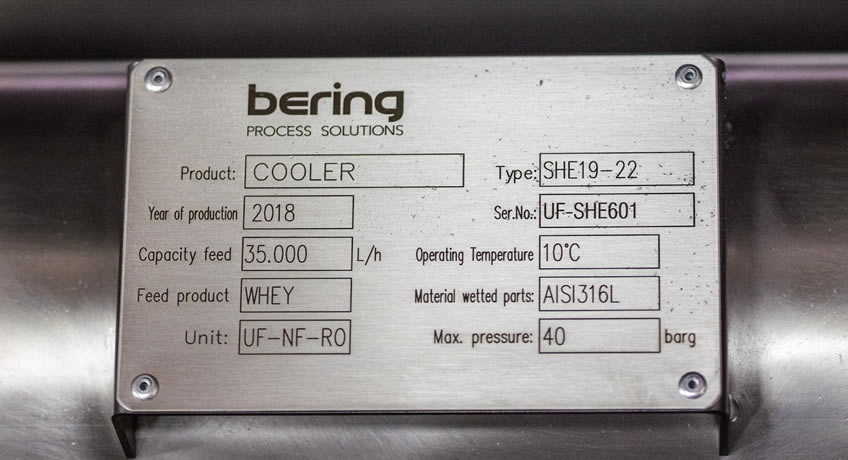

We are working with the leading equipment provides to be on a cutting edge of the technology. Our design engineering solutions are independent from equipment vendor offering optimal combination for the client.

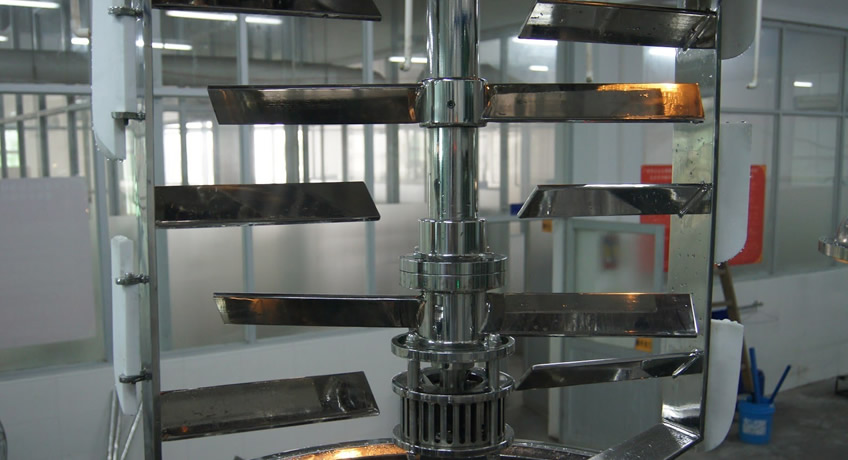

Equipment for whey and milk fractioning

Decolourisation of lactose, whey or permeate, deodorisation of milk

.

Milk pre-treatment: reception, storage and distribution. pasteurization, separation etc.

Utility and process water preparation and distribution systems

Automated cleaning systems (CIP)

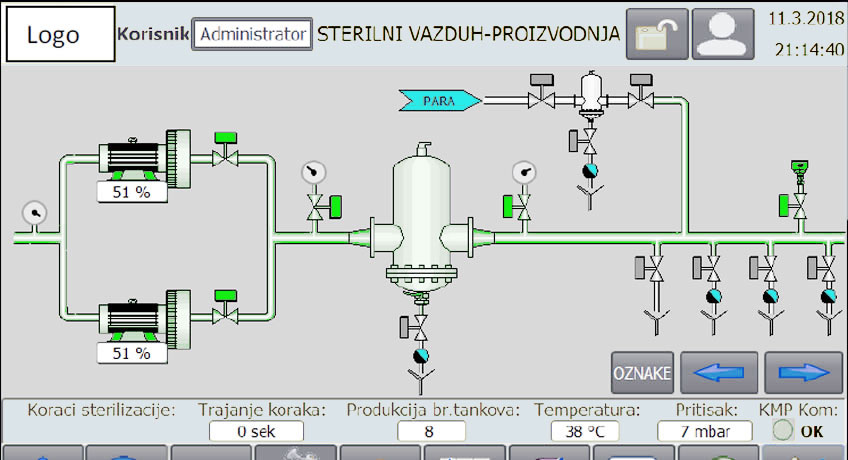

Sterile/filtered air overpressure systems

Other equipment as valve collectors, tube HE.

Ultra-filtration membrane separation systems

Nano filtration membrane separation systems

Reverse osmosis membrane separation systems

Production Gallery

Post-Sales Support

Our commitment extends beyond project completion. We provide technical support, maintenance, and spare parts to ensure your plant continues to operate safely, efficiently, and in line with the latest performance standards.

Post-Sales Support

Maintenance services

Bering offers own “know-how” maintenance and support solutions, which allows to ensure smooth work of a production line or an entire plant.

Skilled field service engineers are at your service to make sure you get an optimum return from your maintenance investment.

Maintenance Services include:

- Preventive maintenance

- Corrective maintenance

- Production support

- Maintenance management

- Performance validation

- Equipment assessment

Parts and components

Bering offers the quality parts and components services from reliable producers.

- Make delivery plan with customer tailored to the specific needs

- Ship on time

- Different logistic solutions tailored to your needs

- Express delivery option

Parts and components are tested and certified for food industry applications.

GET WHAT YOU NEED WHEN YOU NEED IT

Ready to strengthen your processing operations?

Our engineers are available to discuss system improvements, new installations, or upcoming project requirements.

Short pre-project conversations are non-binding and confidential.